At its simplest, warehousing involves the storage of things. At its most complex, it involves logistics management and distribution networks. Companies want smarter warehousing where they know the location of all items. They want to track items coming from the source or going to its next destination. To do this requires a multifaceted, multi-enterprise process.

The Challenge with Multi-Enterprise Business Networks

Building a multi-enterprise process isn’t easy. That’s because ERP and other system vendors develop with a single enterprise in mind. Warehouse operations

and processes require multiple parties to collaborate, plan, and execute.

Few companies can do the entire process when it involves:

- Sales and operations planning (S&OP)

- Quote to cash

- Procure to pay

- Order to ship

- Transportation management

- Demand forecasting

This list doesn’t touch on suppliers, carriers, banks, insurance, or customers. Technology advancements like blockchain, artificial intelligence, Big Data, and the Internet of Things (IoT) are making it possible to develop multi-enterprise networks to connect all the companies to warehousing. Fortunately, new distribution technologies exist to optimize and automate warehousing processes.

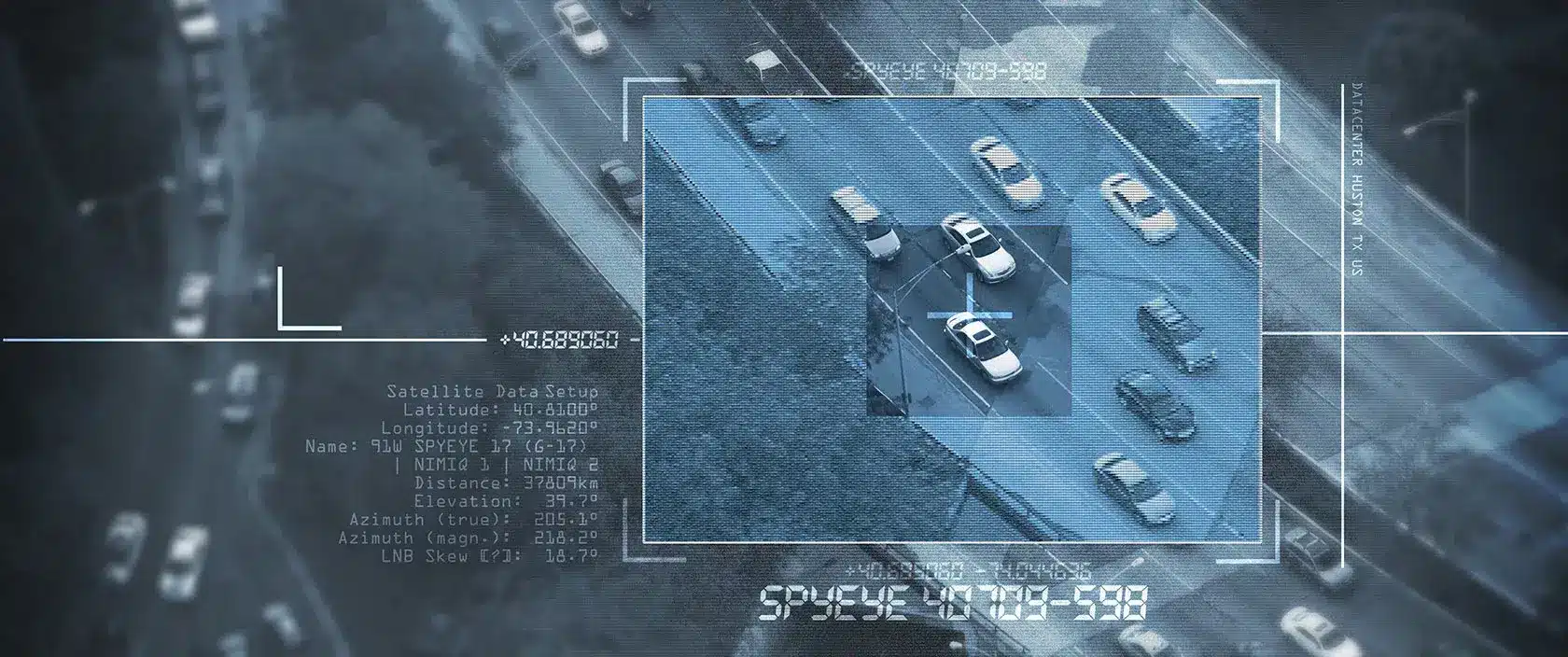

Sensors and RFID Tags

These technologies provide visibility into the inventory and supply chain. Logistic managers can use these to track every single item in a warehouse from their arrival to their departure. The more accurate inventory and product data are, the better the communications among multiple parties.

Tracking data can improve order processing speed, as well as planning and forecasting. Add GPS to RFID and companies can track shipments with higher precision and in real-time. Sensor and RFID tags can decrease counterfeiting and notify employees about low product lines and incorrect SKUs. They eliminate the need for conducting time-consuming audits.

Wearables

Wearables can keep track of employees, stop them from entering unsafe areas, deliver notifications, and monitor health levels. When companies implement wearables, warehouse staff can do more hands-free operations and save time. Employees won’t have to do data entry or take many steps to receive information.

With the decreased demand on staff comes the enhanced performance and decreased training time. Because they’re connected to the network, they amplify operational efficiencies by enriching communication to and from the users. Since wearables connect to the network, management and third parties can check the status to get the most current information.

Artificial Intelligence

Warehouse robots with integrated AI allow them to select the best picking routes. This saves staff time since they’ll take the most efficient routes and avoid long or unneeded trips around the warehouse.

AI and robots can take over the mundane and repetitive tasks to boost productivity. Rather than replacing humans, the World Economic Forum says AI may create as many new jobs as they displace.

No doubt, warehousing technology innovations will have a positive impact on the supply chain. Companies that adopt the right technologies will gain an edge in a very competitive environment.

Warehousing security is another critical component. The right security monitoring vendor can design and implement a security solution that works with the warehouse processes. To learn more, please contact us.