It has been nine months since the Ever Given container ship notoriously blocked the Suez Canal causing a backup of more than 400 ships. The incident alone cost $400 million per hour in goods or $5.1 billion each day according to the CNBC article that quotes Lloyd’s List.

You would think by now that the supply chain would be back on track. Unfortunately, that is not the case. The supply chain continues to remain precarious. In fact, an ABC News story reports that supply chain problems will most likely get worse before they improve.

Moody’s report states that despite the progress of global economic recovery, supply chain problems will continue to affect everyone including businesses and consumers.

What’s Causing the Supply Chain Problems?

The short version is that the pandemic is to blame for the supply chain backlog and disruptions. The aforementioned ABC News article contains a perfect quote that says it all.

“The result of that imbalance between supply and demand eliminated all the inventory and eliminated all the grease that allows the wheels of commerce to work smoothly,” said Steve Ricchiuto, chief U.S. economist at Mizuho Securities.

The following three things are the biggest factors affecting the supply chain.

1. Increase in material prices

It’s not your imagination. The price of materials has hit the roof. Construction Dive shows the explosion of material costs that began after the pandemic. Many factors have created a perfect storm for the highest increase not seen in decades.

National Association of Home Builders

indicates the following have caused the soaring price of materials:

- Mills closed due to state and local government lockdown measures.

- Reduced capacity of mills and factories due to predictions of plummeting demand.

- Unexpected flood of do-it-yourself projects going to big-box retailers.

- DIY demand stayed strong after lock down ended.

- Housing market during the pandemic did better than expected.

- Demand for construction far exceeded the forecast.

These things created a disparity in supply and demand. As suppliers try to catch up, companies are having to submit orders without a delivery date or cancel them altogether. And the storm is the gift that keeps on giving. Lumber tariffs on Canadian imports into the U.S. have climbed by more than an average of 20 percent.

2. Shortage of workers

The crisis has caused companies including lumber yards, construction companies, and factories to experience a scarcity of workers. Before companies could bring workers back on, they had to change their processes to ensure worker safety. When they were ready to bring workers back, they struggled to reach capacity.

Many workers may have become ill or had to take care of a sick family member. They may have young children who could not be left home alone. By the time the companies had enough workers, the backlog grew, and they have not caught up.

3. The law of supply and demand

If you’ve been reading this blog, you know supply and demand has come up quite a bit. It’s truly the cause of all the shortages. Manufacturing did not have enough workers to produce what is needed to keep fueling the supply chain. Hence, the shortage led to greater demand.

The shutdown, the lack of workers, shipment delays, and increase in construction and DIY projects all drove up demand while supply snarls continue for the foreseeable future.

In its 35 years of tracking the cost of construction materials, Associated General Contractors of America

indicates the industry has experienced the highest ever monthly and yearly increases. The situation compelled AGC to issue a construction inflation alert, which sums up all the causes of the supply chain problems.

“The construction industry is currently experiencing an unprecedented mix of steeply rising materials prices, snarled supply chains, and staffing difficulties, combined with slumping demand that is keeping many contractors from passing on their added costs,” says AGC. “This combination threatens to push some firms out of business and add to the industry’s nearly double-digit unemployment rate.”

It’s not just the shortage of materials causing the prices to go up. Thefts are also driving up the prices for many products including smartphones, TVs, video game consoles, and food.

All of this leads to an increase in cargo theft.

Why Cargo Theft Continues

CargoNet tells CBS News that companies reported about $45 million in cargo theft between January and September 2021. This is on track to surpass the $49 million for all of 2019 and almost match 2020’s $68 million in cargo theft.

Keith Lewis who oversees CargoNet’s operation does not expect to see that changing for a few years. He also says much of the cargo theft takes place when trucks are parked. Unfortunately, it’s difficult to determine where the pilferage occurred because truck drivers often don’t know something is missing until later in their route.

A typical truck route has multiple stops in multiple municipalities. It makes it difficult to determine where the theft happened. Because of this, they don’t know which law enforcement to contact to file a report. Thus, cargo theft is largely underreported. Many companies choose not to report cargo theft for fear of bad press and rising insurance premiums.

Additionally, cargo theft is greatly underreported due to the lack of a centralized database tracking thefts. No single system tracks all reports of cargo thefts. Besides that, two different cargo theft tracking tools may categorize or define crimes differently.

It’s a Catch-22 situation. The increasing costs for products are leading to cargo theft. Cargo theft is growing because crooks can get more money for the stolen goods.

The Need to Prevent Cargo Theft

There is already a shortage of many things due to the supply chain logjam. Now, cargo theft is aggravating that shortage. Anytime thieves steal something that’s in demand, it greatly diminishes supply.

Take for example, computer chips are in short supply. Savvy thieves know this and will track down chips to steal. Once they do, the company shipping the chips has to replace those stolen chips. That is harder to do because of the shortage. When customers can’t get their products in a timely manner, they may take their business elsewhere.

This is why it’s critical to take steps to prevent cargo theft from happening in the first place. Moreover, replacing stolen goods will cost a bit more than what your company paid for the original item. In other words, it will take a lot of sales to make up for the stolen products.

Just look to SupplyChainBrain, which cites a study of stolen digital cameras worth $200k. To offset the loss, the company would need to make 10 times the number of sales totaling $2 million.

CargotNet says the average loss value from a cargo theft is $144K. Based on the study referenced in SuppleChainBrain, the company will need to see $1.4 million in sales to make up for the loss of the stolen items. In addition to this, the stolen items were most likely made with materials that cost a lot less than they currently do.

To make a long story short, the delicate supply chain and growing costs require companies to take steps to deter cargo theft. Otherwise, they put customer loyalty, revenues, and brand reputation at risk.

The Best Way to Prevent Cargo Theft

The best way to protect your cargo is with layered security. Create security processes and train employees on those processes and basic security protocols. Companies should run background checks on all drivers and new employees.

You can change processes and procedures to create a more secure one. For instance, you can revise the shipment process by requiring trucking partners to provide information to your company at least 24 hours before pick-up. The information will need to have the name of the driver and carrier, truck number, and insurance details.

Avoid packing the trailer until right before the truck is scheduled to depart. When revising the process, make it a requirement to avoid packing trailers the night before they depart. Thieves will go after parked trailers in the dark. Don’t release a load to the driver until your employees take photos of the driver, truck, and bill of lading as well as capture the driver’s fingerprints.

Avoid displaying identifying information on the package or tractor-trailer that reveals what’s in it. This may not stop someone who will take the risk to steal a trailer not knowing what it contains. Still, it can reduce temptation. Some criminals won’t steal something without knowing what it is.

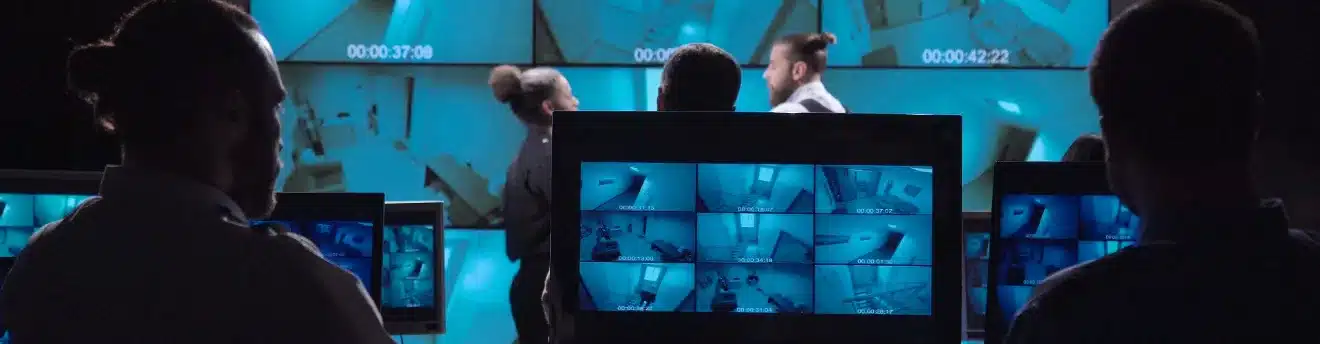

Also, add video surveillance with remote monitoring. This takes a proactive approach to security and helps avert crime. The high-resolution cameras can make out faces and other identifying information. If the theft occurs outside of monitoring hours, you can have analysts search video surveillance footage to piece together what happened and share the information with law enforcement to help make an arrest.

Not all video surveillance system cameras work well or provide proactive security. The most effective video surveillance system integrates high-quality security cameras with video analytics and human monitoring operators. The partnership between analytics and monitoring operators will help increase the chances of their catching something suspicious before it happens.

The right remote video surveillance system delivers a quick return on your security investment. The high costs of materials more than justify the need for security. You’ll help protect your cargo and your employees.

To learn more about video surveillance and how it’s possible to do more than deter cargo theft, check out the guide to Remote Video Surveillance: More Than Just Catching Criminals. For a customized security plan that fits your requirements and maximizes your ROI, contact us.