Several social media and news outlets have been abuzz recently about what seems like an unusual number of fires in food manufacturing plants. So far this year, there have been at least 16 instances of fires.

Among the 2022 fires are:

Azure Standard – April 19

Taylor Farms Processing Facilities – April 13

Penobscot McCrum potato processing plant – March 24

East Conway Beef & Pork – April 12

A Nestle plant– March 16

Shearer’s Foods potato chip plant – February

Wisconsin River Meats – February 3

Cargill-Nutrena plant – January 13

A poultry processing plant – January 6

While most of these fires were accidental, they did begin to spark conspiracy theories claiming they are being set intentionally to sabotage our nation’s food supply. The theories were spreading so fast that the fact-checking website Snopes got involved. They determined the claims were false, stating, “The claim of a new ‘trend’ of fires at food processing facilities does not hold up upon scrutiny. Almost all of the fires on meme lists involved explainable causes, and we found no examples of suspected arson. One of the included examples involved an abandoned building, while another involved a butcher shop (not a large food processing facility). Most importantly, this ‘trend’ is not new. When we searched for news stories about fires at food processing plants in 2021, 2020, and 2019, we found that such fires are relatively commonplace, and that there have not been any conspiracy-worthy upticks.”

The Need to Enhance Security at Food Processing Plants

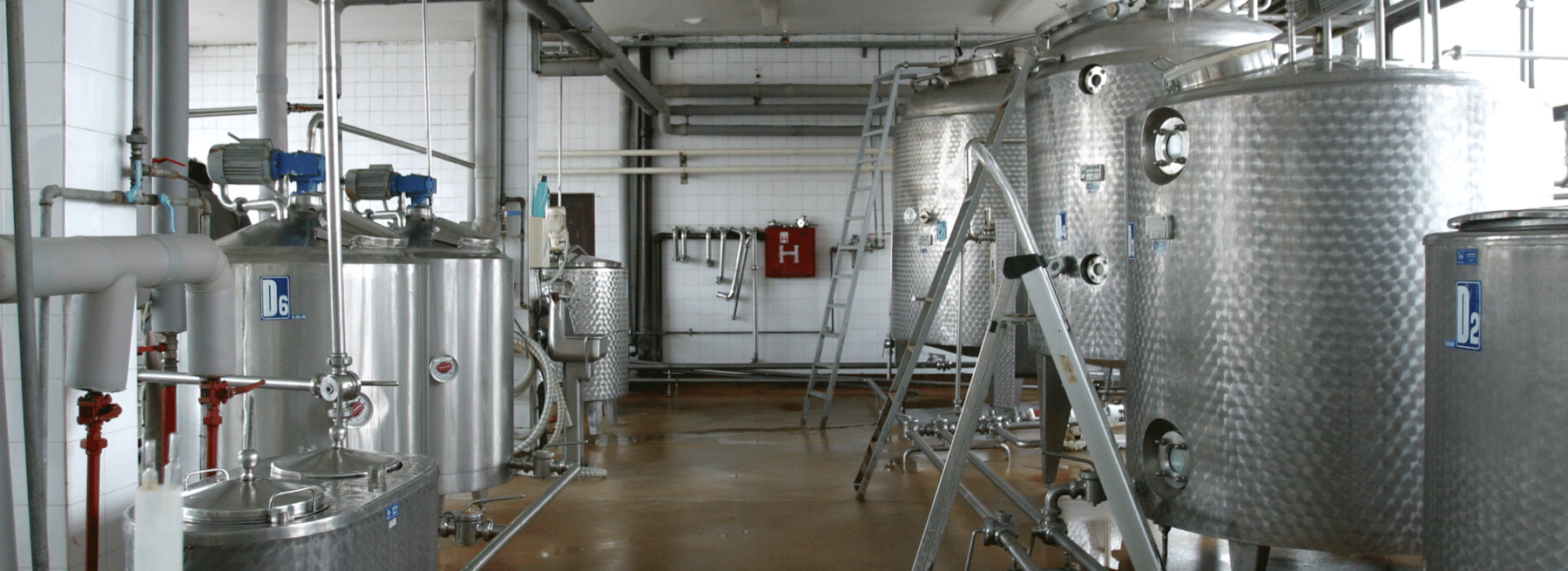

Despite the fact these conspiracy theories have been debunked, they do illustrate the strong need for security at food processing plants that face operational and security risks every day. Ensuring food safety is especially important for the industry, as well as the supply chain, which is why many plants are turning to video surveillance and access control systems. These not only help control who can enter the building, but also enhance security and production.

Surveillance cameras can be installed at key locations in and around a food processing plant. These include entrances to the facility and processing areas, loading docks, storage areas and the perimeter of the property. The cameras alone could be enough to deter someone with ill intentions. However, on their own, the system is purely reactive. The cameras will record all activity and the footage can be used for evidence as needed. While this is beneficial, most incidents would come to light after the damage has occurred.

When you add video analytics and security personnel to watch those cameras in real time, you now have a proactive solution that can help deter theft and damage BEFORE it happens. Let’s say someone is trying to enter the facility after hours. The cameras could pick up that activity and alert a monitoring operator as it is happening. The operator can quickly evaluate the situation and act accordingly. This could involve activating an on-site speaker to warn the intruder they are being watched, as well as call to dispatch local authorities.

Operational Benefits of Video Surveillance at Food Processing Plants

In addition to being a proactive crime deterrent, video footage can be used to enhance operations and train employees. For example, Renfro Foods, a Texas-based manufacturer and distributor of gourmet salsas, sauces and relishes, uses video footage to teach their employees proper processes, including checking to see whether an ingredient was added to a specific batch. In addition, their production managers can watch various shifts from their phones and provide feedback.

When it comes to securing a food processing plant, or any type of manufacturing facility, it’s important to prepare for the unexpected. Don’t wait for something to happen. Being proactive can help save a facility from crippling losses.

Be sure to check out our update on this topic here: Follow-Up: Food Processing Plant Fires in the News

If you would like more information about live video monitoring for your business, contact us.