It goes without saying that safety is one of the highest priorities in the construction industry. Construction management has a responsibility to maintain a safe work environment, and safety requires more than simply thinking about how to create a safe construction site.

Companies with the highest safety records have infused safety into the company culture. How is this approach different? They interweave safety throughout the company. For these companies, safety is everyone’s responsibility, including those who never go to a construction site. They have documented processes and continue to evolve them. As they start planning for a new project, they create a plan for the jobsite and organize the construction site to increase both safety and productivity.

The construction industry has lagged in terms of applying technology to projects according to McKinsey and Company research. The report describes how most industries have adapted quickly by investing in technology while construction technology trailed. As a result, construction productivity has fallen behind compared to all other industries.

Fortunately, it has started to change in the last couple of years. One factor is the retirement of Baby Boomers in droves. The people replacing them are the digital natives, Millennials and Generation Z.

A JBKnowledge ConTech survey of construction workers referenced in Building Design + Construction has found that IT staff has grown by more than 36% over the last year. Many use their devices in their daily work. The No. 1 reason for using mobile devices in the field is daily reporting, followed closely by photo and video, time management, and safety management.

Besides improving productivity, construction technology offers another major benefit: it can mitigate construction safety risks. With digital-savvy generations entering construction and the increased use of connected devices, it’s a great time to invest in construction technology. Here are some options.

1. Sensors and Internet of Things (IoT)

Sensors and the Internet of Things (IoT) can be integrated into equipment and wearables. The sensors and IoT may work with Wi-Fi, GPS, or radio frequency identification (RFID) to make it possible to track workers and equipment. It’s simple to insert them into vests, boots, and pants.

Technology like Caterpillar’s Cat MineStar Detect can detect a problem and send a notification. The way Cat MineStar Detect works is that you put the RFID tags into personal protective equipment (PPE) like safety vests and hard hats. The tags can monitor equipment and workers for potential fatigue and distraction in real-time. They will alert the person operating the large equipment anytime someone is behind them.

2. Business Information Modeling (BIM)

Business information modeling (BIM) is a powerful construction technology that can model complicated work processes for the entire project. BIM helps the architecture, engineering, and construction teams effectively plan, design, construct, and manage buildings and their infrastructures.

You could say that BIM is like 3D CAD 2.0, since it contains more details. BIM has the ability to render the building in 3D. This model is interactive and can spotlight different systems, such as showing how the HVAC operates. BIM also shows quantities, performance, and personnel requirements.

Some contain a project management element. This component tracks the costs and allows people to oversee the planning, design, and building of a project from start to finish. The project documentation helps provide context.

BIM simplifies revamping a model. For example, after the pandemic hit, a project team needed to revise the plans to incorporate contactless technology. The manager can change the architecture and visually see how it will look and function and can run simulations to verify it works as expected and safely. This shortens construction time and limits cost overruns associated with modifying the building.

What does all this have to do with safety? It offers safety risk management tools. Remember, it has powerful 3D visualization capabilities. This lets users be proactive in identifying and addressing potential safety problems early on. BIM can also be a repository for safety resources.

3. Robots and Drones

The Commercial Construction Index states more than half of the respondents struggle to find qualified workers. Automation with robots and drones can ease the labor shortage problem. They can handle tedious tasks, and often do it faster.

Initially, many eschew the thought of using robots and drones. They worry that robots and drones will replace workers and jobs. This isn’t the case. Rather, automation boosts productivity and accuracy as the workers do high-value tasks. At the same time, it cuts overhead and waste. These technologies can help close the gaps associated with the worker shortage.

A good example of this is Construction Robotics’ Semi-Automated Mason (SAM 100). The technology can lay more than 3,000 bricks per day. All the workers need to do is restock bricks and mortar into SAM. They also do clean up around the bricks.

A project without SAM typically needs four or five masons and two foremen. Training the workers on how to use SAM only takes a week. With SAM, you can reduce the number of workers from six or seven people to four with one mason, one foreman, and two laborers. Not only does this speed up the work but also increases safety for the workers.

SAM 100 can lay 380 bricks per hour. A bricklayer averages about 500 bricks per day. It only takes SAM 100 two hours to surpass the bricklayer. The collaboration between the masons and technologies cuts lifting by 80% and speeds productivity by three to five times.

As for drones, they can do site inspections, review project progress, and locate potential hazards to improve safety. Management can use them to check materials, machines, and workers, all without going to the construction site. Managers can also use it to scan the jobsite for potential hazards to improve safety.

Some companies use drones to analyze the site for geological problems. They can obtain more accurate survey estimates of geological conditions. When caught early, it prevents schedule overruns. Robots and drones allow management to safely monitor from a location away from the jobsite.

4. Safety Compliance and Risk Management Apps

Safety compliance apps use checklists and forms to streamline the tedious process of recording hazards and safety episodes. This gives teams the capability to identify and resolve safety issues quickly. As a result, it prevents potential injuries. Safety compliance apps can combine commissioning and inspection apps for safety compliance reporting.

Risk management is a proactive tool as it can lower the risk of injuries. These types of apps centralize document management and put them in the cloud for anytime, anywhere access to safety information. These documents include injury and incident reports, equipment operation manuals, training records, and safety data sheets.

5. Remotely Operating Machines

Recall that Baby Boomers are retiring and digital natives are replacing them. However, these digital natives may not want to operate a machine on the jobsite. Remotely operating machine allow the more tech savvy to work miles away from the site by interacting with simulators that allow them to operate a machine.

It’s similar to drones in that pilots can be located anywhere away from the place of operation. The benefit of remotely operating machines is that it keeps the operator out of harm’s way and puts fewer people on the jobsite.

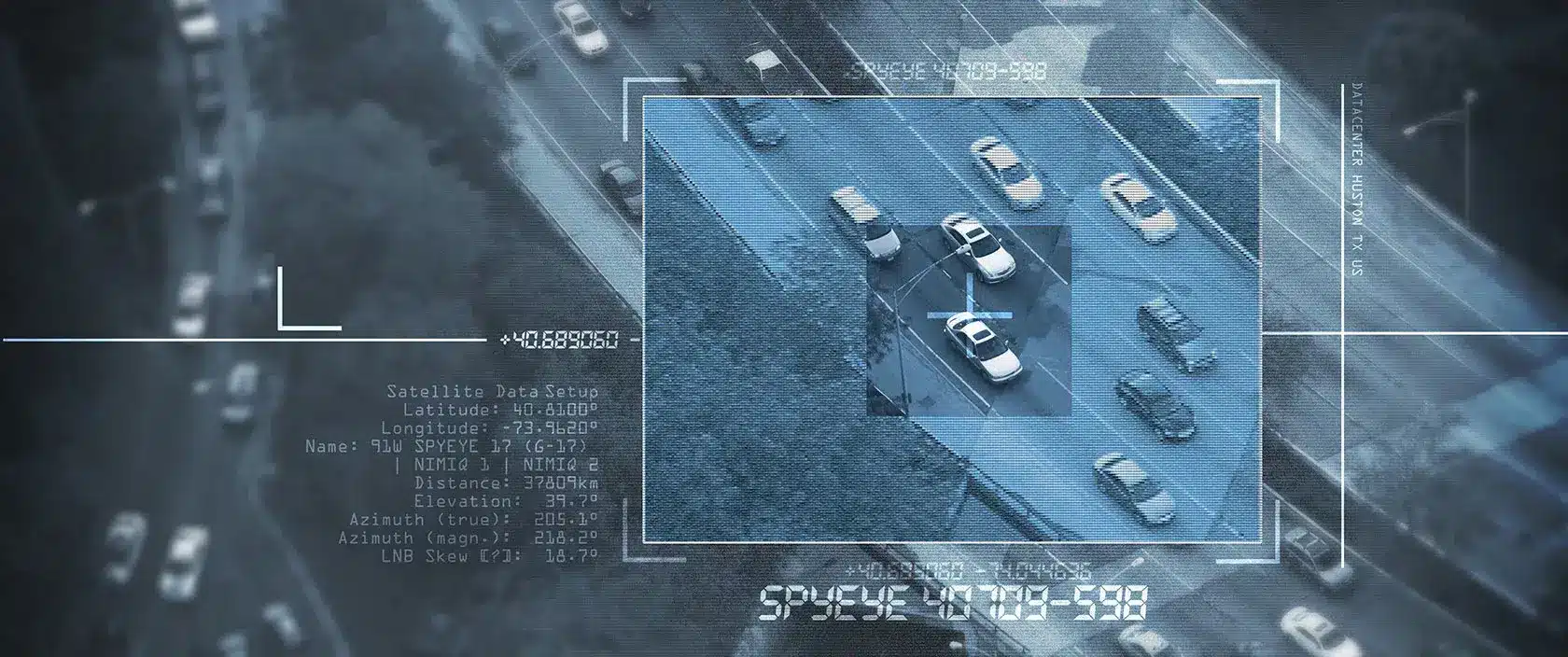

6. Video Surveillance with Remote Monitoring

Remote video surveillance provides the highest level of construction safety. An effectively designed security camera layout with remote monitoring service has the ability to see the entire construction site and saves all activity as recordings.

This proactive safety and security technology involves placing security cameras around the jobsite. Trained monitoring operators work with video analytics to observe the site for problems and report them as they arise. Because they’re proactive, they can help lower risk and liability while delivering a fast return on investment.

Construction companies that use remote video surveillance work with a security vendor. The vendor has a monitoring center located away from the construction site. These centers contain trained monitoring operators working with video analytics to watch over the site around-the-clock. The monitors are never in danger, and this lets them respond to suspicious situations without fearing for their lives.

It’s monotonous for humans to monitor video for hours at a time. It puts the monitor at risk of missing something important. That’s why it’s critical to have video analytics. They take over the most taxing part of monitoring while the humans do the decision-making. Security vendors program many scenarios related to detecting and tracking people and vehicles. Video analytics scans for these scenarios and alerts the monitor when they spot a questionable one. The trained monitor checks it out and responds as needed. This could be issuing an audio warning to the suspect through a two-way speaker, calling law enforcement, contacting the manager, or all of the above. They can also provide feedback to video analytics to help it grow smarter.

When interviewing remote video surveillance companies, look for one with construction industry experience. You don’t want to risk anyone’s safety in working with a company that doesn’t know construction and its unique challenges.

Construction Safety

Once again, construction safety needs to be part of the company culture. This means reviewing and updating processes related to safety. Construction technology can remove a lot of the tedium from the processes.

When you incorporate some of these solutions, you’ll reduce the risk. Video surveillance with remote monitoring has the greatest chance of doing this because it gives you a bird’s-eye-view of the site. Video analytics and the monitoring operators can watch for safety hazards and report them before anything happens.

To delve into this topic, check out the construction security and safety best practices guide. This detailed guide discusses industry challenges and offers solutions. If you’d like to know more, contact us. Texas Private Security License Number: B14187